Recognizing the standards and methods surrounding electrical test and tag treatments is vital when it comes to making sure electrical safety in Western Australia. One essential aspect that is usually gone over in this field of job is the use of specific tag colours, which offer both practical and useful functions. In Western Australia, the tagging system typically uses a colour coding plan that indicates the condition of the electrical equipment and whether it has undertaken testing. Eco-friendly tags are typically utilized for appliances that have passed testing, while red tags indicate that an item has actually fallen short and ought to not be made use of up until it is repaired or retested. It is critical for businesses and facilities to follow these tagging conventions to preserve compliance with workplace health and wellness regulations.

The importance of test tags can not be overstated in avoiding electrical risks within the workplace. Test tagging is not almost attaching a tag to equipment; it is a thorough procedure that includes extensive testing to make sure that electrical tools adhere to Australian safety standards. In Western Australia, the procedure usually calls for adherence to the AS/NZS 3760 criterion, which lays out the requirements for the in-service safety inspection and testing of electrical equipment. This typical serves as a guideline for testing numerous kinds of electrical devices to guarantee they are secure for usage, which is an essential component of workplace safety compliance.

The most appropriate include AS/NZS 3760, which outlines the treatments for inspecting and testing electrical home appliances, and AS/NZS 3012, which concentrates on the electrical setups in building and construction and demolition sites. Both standards are created to mitigate dangers linked with electrical risks and are necessary for companies that wish to make sure the safety of their clients and staff members.

In New South Wales (NSW), for circumstances, electrical testing and tagging standards might have mild variants from those in Western Australia, yet the underlying concepts are regular across the country. The NSW policies necessitate that workplaces carry out electrical safety examinations consistently to determine any malfunctioning equipment.

In NSW and across Australia, organizations are progressively identifying that preserving a clear system of electrical safety checks not just leads to compliance but additionally reduces downtime created by equipment failure. These companies utilize certified specialists who are educated to follow safety procedures and provide extensive reports describing their findings throughout the inspection process.

One more critical element of this whole process is the electrical safety certificate. As soon as an extensive inspection and testing have actually been conducted, companies commonly receive a safety certificate that confirms compliance with pertinent industry standards. This certificate supplies assurance to management and workers alike that all essential safety measures have actually been required to ensure safety. In addition, it can be an important possession throughout audits by relevant regulative bodies. Organizations that can show their dedication to electrical safety through appropriate paperwork and certificate issuance are usually viewed much more positively throughout compliance checks.

Electrical safety evaluations are not solely concerning compliance; they mirror a commitment to the welfare of staff members and clients. By regularly resolving safety problems and carrying out steps to rectify any kind of determined problems, companies foster a setting of trust fund.

The landscape of safety compliance is continually progressing, with the introduction of new modern technologies and approaches. Keeping abreast of these growths is vital for safety professionals, as they boost not only the precision of testing yet also the efficiency of the maintenance processes.

Workplace health and wellness services play a pivotal role in promoting electrical safety amongst services. These services are often extensive, encompassing risk assessments, safety audits, training sessions for workers, and recommending on compliance with regional policies. When companies buy these services, they are not only ticking boxes to satisfy lawful requirements-- they are actively pursuing producing a society of safety that permeates every element of their procedures. This proactive technique identifies that it is not almost meeting standards, but about really focusing on the safety and well-being of individuals in the workplace.

Another emerging pattern in electrical safety is the concentrate on recurring education and learning and awareness. As technology develops and new threats emerge, so as well should the understanding of those in charge of keeping electrical safety. Normal training sessions are essential, guaranteeing that workers and safety workers are knowledgeable regarding the most up to date methods, dangers, and regulative modifications. Lots of organizations are read more now integrating e-learning modules that offer flexibility for busy professionals, hence making it simpler to stay updated on safety methods and procedures.

These organizations manage safety requirements and supply crucial guidelines that promote the health and safety of employees throughout different sectors. Their ongoing research, advocacy, and advancement of safety campaigns play a crucial role in shaping the landscape of electrical safety guidelines.

Repair and maintenance of electrical equipment additionally add significantly to guaranteeing workplace safety. On a regular basis set worksafe australia up maintenance checks recognize possible threats prior to they bring about mishaps or failures. Companies are strongly recommended to integrate precautionary maintenance routines into their operational plans to reduce risks related to electrical equipment. This also encompasses training maintenance staff, guaranteeing they recognize the requirements of testing and tagging and are totally outfitted to recognize malfunctioning elements.

The significance of electrical safety spans a vast variety of markets, from construction and making to health care and hospitality. Every company has a responsibility to promote safety standards, not even if it is legitimately mandated however also due to the fact that a failing to do so can have dire effects. The danger of injury, death, and considerable financial effects is ever-present. Hence, prioritizing electrical safety with testing and tagging, routine assessments, and compliance with market standards is necessary for promoting a productive and safe job setting.

To keep this safety, workplace health and safety services, ongoing training, and compliance with well established standards create the foundation of an efficient safety method. Inevitably, companies that focus on electrical safety not just abide with regulations however show a real commitment to the well-being of their workers, cultivating a society in which safety is viewed as a critical value.

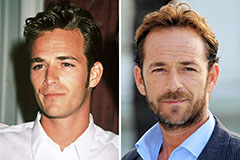

Luke Perry Then & Now!

Luke Perry Then & Now! Kelly McGillis Then & Now!

Kelly McGillis Then & Now! Alexa Vega Then & Now!

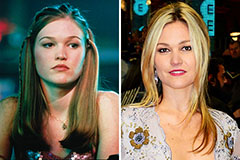

Alexa Vega Then & Now! Julia Stiles Then & Now!

Julia Stiles Then & Now! Erika Eleniak Then & Now!

Erika Eleniak Then & Now!